Low-Cost Batched PCB’s

Low-Cost Batched PCB’s

Pad2Pad makes it easy for you to get a small quantity of full-feature circuit boards without paying production prices. By processing multiple short-run jobs simultaneously, we’re able to offer batched PCB’s economically. Use this low-cost PCB fabrication service to build rigid, 2-layer boards up to 5 x 7” with HASL plating, top side silkscreens, and solder masks. Stick to your budget and get the high-quality, electrically-tested PCB’s you need by getting your quote today!| Feature | Batch PCB’s |

|---|---|

| Number of Layers | 2 |

| Order Quantity | No limit |

| Board Type | Rigid |

| Board Shape | Any (rectangular, round, slots, cutouts, complex, custom) |

| Board Material | FR4 epoxy glass |

| Board Cutting | Tab-routed |

| Board Thickness | .062″ |

| Copper Weight | 1.0 oz |

| Solder Mask | 2 sides |

| Solder Mask Color | Green |

| Silkscreen | Top side only |

| Silkscreen Color | White |

| Silkscreen Minimum Line Width | .006 in |

| Maximum Board Dimensions | 5″ x 7″ *Total area up to 105 sq in |

| Minimum Trace | 0.006″ |

| Minimum Gap | 0.006″ |

| Drill Sizes | Any |

| Minimum Drill Hole Diameter | .010″ |

| Plating Options | HASL |

| Surface Finish | HASL |

| Board Thickness Tolerance | ±10% |

| Board Outline and Internal Cutouts Tolerance | ± 0.005″ |

| Copper Weight Tolerance | ±10% oz |

| Minimal Slot Width | .02 in for plated thru-hole (PTH) 0.03 in for non PTH |

| V-score Depth | 33.3% of board thickness |

| Minimum Annular Ring | .006″ |

| Plated Through Holes | Yes |

| Supported Formats | Gerber X2 Gerber RS-274X Pad2Pad |

| Turn-around Time | 7-18 days |

| Electrical Testing | Flying probe |

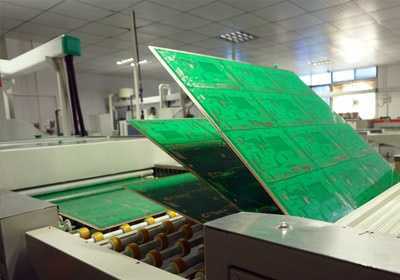

What are Batched PCB’s?

PCB Batching is a production technique where boards from different orders are pooled together onto one panel. The boards are fabricated only after the panel is full. Because the setup cost is distributed among all customers in the pool, batched PCB’s are lower-cost than if the same order was manufactured as a single job. Batching is popular for budget-sensitive, low volume circuit board projects.

Ready to order?